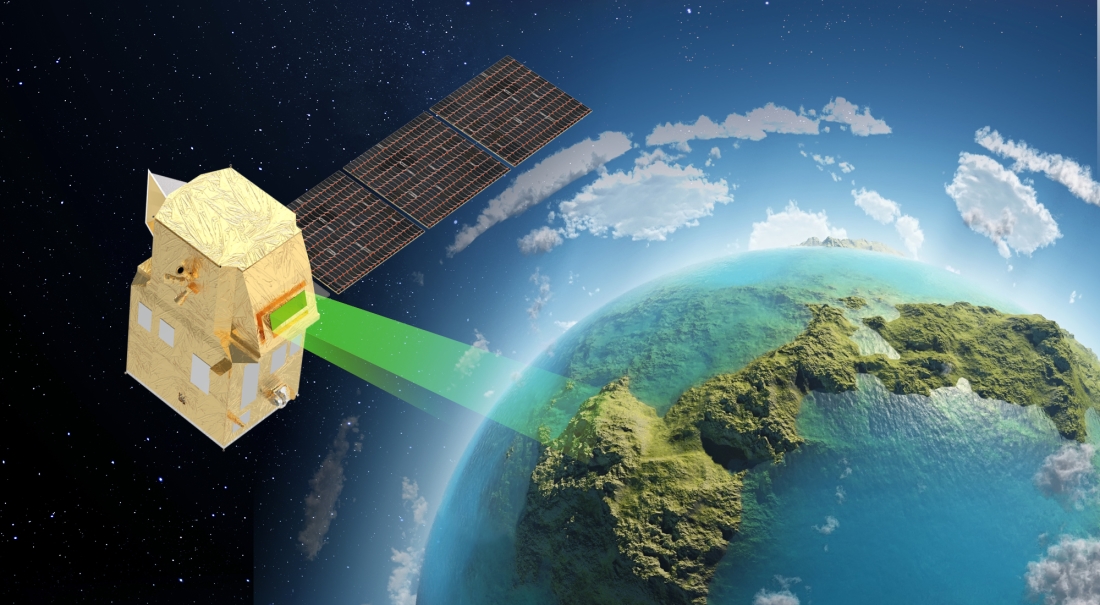

Newest Satellite Missions

ALLFedEO

FedEO (Federated Earth Observation missions access) provides a unique entry point to a growing number of scientific catalogues and services.Browse missions by agency

Observing the Earth

The articles on this website are based on contributions from Herbert Kramer, author of the book “Observation of the Earth and its Environment”.